What is a progressing cavity pump?

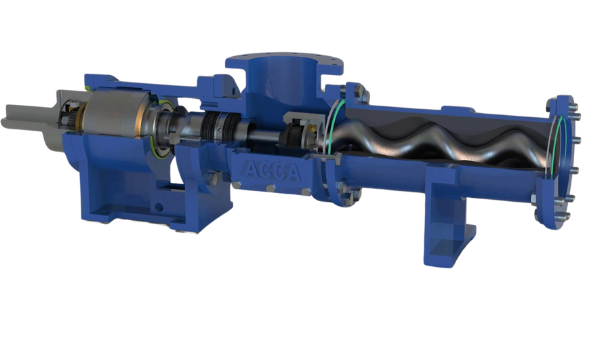

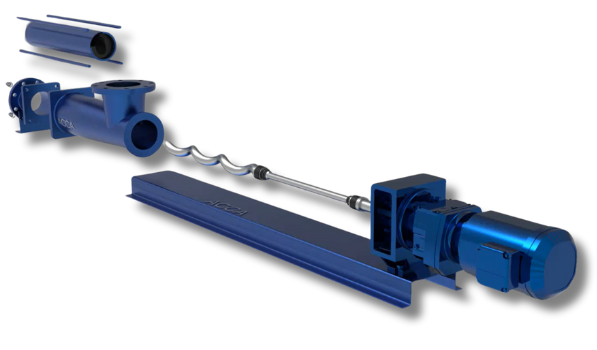

The progressing cavity pumps are distinguishable from other types of positive displacement pumps due a helical rotor (worm) and stator. These create cavities (also known as chambers) which are specifically designed to facilitate pumping of higher viscosity fluids such as slurries, thick oil, solids, molasses,chemicals and additives. The nature of the design is rotary and is categorized as a positive displacement pump but the uniqueness of the internal worm and stator enable low shear and smooth pumping while in operation when other designs struggle.

In the United States, the progressive cavity’s eccentric design method has also been widely accepted as a reliable way to pump crude oil and drilling mud.

Featured Company of the Month

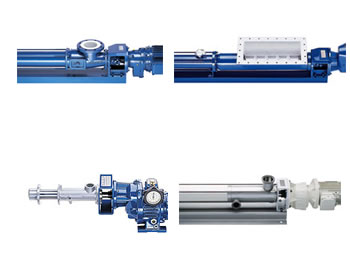

ACCA Progressive Cavity Pumps are engineered for optimal performance in handling high-viscosity fluids, slurries, sludges, and shear-sensitive liquids. Known for their efficiency and durability, these pumps are ideal for demanding applications. Our team of experienced Application Engineers is ready to assist with everything from design to manufacturing, ensuring you get the right pump for your needs.

If you’re looking to replace an existing pump without modifying your baseplate or piping, we will guide you through the selection process and provide follow-up support after installation to ensure the pump performs as expected. ACCA Pumps are designed to be compatible with other leading Original Equipment Manufacturers, including Moyno® Pumps and Netzsch® Pumps. These special features are what set our progressing cavity pumps apart, making them the top choice for a wide range of applications.

Progressive cavity pumps are positive displacement pumps, designed to handle high-viscosity fluids, slurries, and shear-sensitive liquids. The heart of this pump lies in its rotor-stator mechanism. As the rotor rotates within the stator, a series of cavities is created, each of which holds a fixed volume of fluid. These cavities move the fluid in a steady, uninterrupted flow, making progressive cavity pumps ideal for transferring substances like chemicals, food pastes, sewage sludge, and more, without altering their structure.

Engineers love this pump for its precision and adaptability. The rotor-stator design minimizes pulsations and shear forces, ensuring the fluid’s properties remain intact. Whether the liquid is thick, abrasive, or sensitive to shear, the progressive cavity pump can handle it with minimal wear and consistent performance. Its efficiency in handling tough applications—like pumping slurries or chemicals—while maintaining optimal flow rates makes it a go-to solution in industries like wastewater treatment, food processing, and chemical manufacturing.

Moyno® 2000

NETZSCH® Pumps

Other progressing cavity pump companies:

UT PUMPS & SYSTEMS PVT LTD

UT PUMPS & SYSTEMS PVT LTD UT Pumps & Systems Pvt Ltd is an ISO 9001-2008 certified company for design and development of Positive Displacement pumps as per designs acquired from European manufacturers by virtue of Joint Venture partnerships. Known as a solution providing company with presence in almost all industries for a wide range of applications

NOV Monoflo

NOV Monoflo Progressing Cavity Pumps, Grinders, Screens, Packaged Pump Solutions, and Universal Parts

Liberty Process Equipment

Liberty Process Equipment Progressive Cavity Pumps Progressive Cavity Sanitary Pumps Progressive Cavity Wastewater Pumps Progressive Cavity Sewage Pumps

HYDRO PROKAV PUMPS INDIA PRIVATE LIMITED

HYDRO PROKAV PUMPS INDIA HYDRO PROKAV PUMPS INDIA PRIVATE LIMITED is one of the Leading Manufacturers and Exporters of various types of Positive displacement Pumps based in In

CSF Inox SpA

CSF Inox SpA Manufacturing of Centrifugal and Self-priming pumps, Progressing Cavity and Rotary Lobe pumps, Air-Operated Piston pumps